dyeing

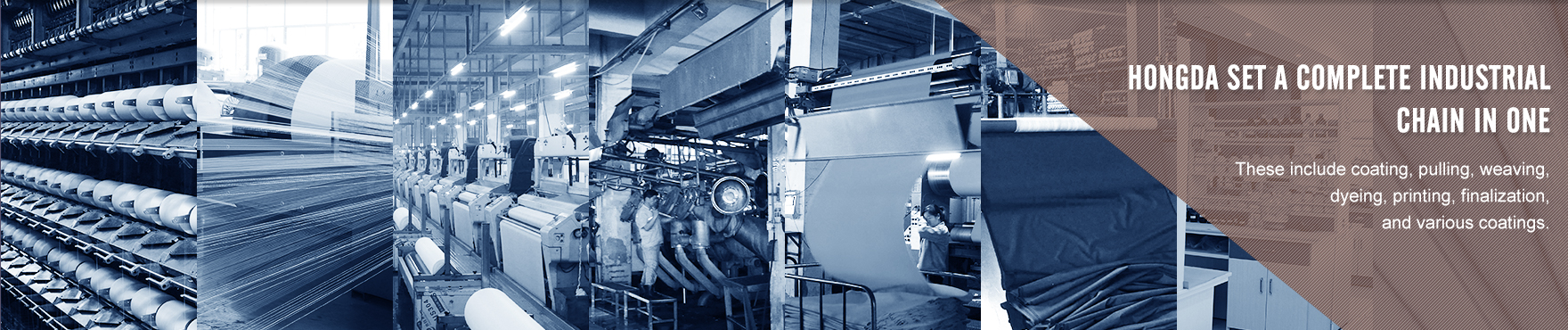

In order to produce better products to meet the changing market. Over the past few years, the company has spent a lot of money to import and buy hundreds of sets of advanced dyeing and finishing, testing, water treatment and other professional equipment. At present, the main equipment of the company is: the programmable energy saving Korean high temperature and high pressure dyeing machine, the joint venture day new setting machine, the original imported type setting machine, the hair machine, the large centrifugal dehydrator, the rewinding machine and the opening machine, with the ability to dye more than 200 million meters a year. In order to ensure the quality of the products, Hongda has invested a lot of funds in testing and testing, equipped with professional testing and laboratory technicians, and introduced the world's first class advanced sample mother liquid drop automation system (LA-600 tube free), automatic color measurement system and various sample sample samples, and the quality of the processed printing and dyeing products is deep. It is accepted by the customers.

Hongda Textile

Hongda Textile